The 8-10t/h poultry feed plant is a complete set of machines that are specifically used to make feed pellets.This feed production line can make feed pellets for chicken, cattle or other animals using raw materials like corn, soybean, wheat and any other grains. Our poultry feed plant can satisfy your requirements by changing die (mold) and feed formula with different equipment configurations.

Category: Feed Pellet Production LineTags: 8-10TPH poultry feed plant, feed mill plant, feed plant, feed production line, poultry feed plant

Our 8-10TPH poultry feed plant is welcomed by the customers for its simple configuration structure, durable quality, low cost and good after-sales service. Our company pushed out a new manual dosing system solution for poultry feed plant mainly contains of feed hammer mill, poultry feed mixer,feed pellet making machine, feed cooling machine and feed pellet bagging machine and so on.

The complete poultry feed production line is simplified for large feed mill without redundant machine. On the one hand this design can save more poultry feed mill plant space.On the other hand the scientific machines arrangements can guarantee the yield to save energy and raw material consumption.

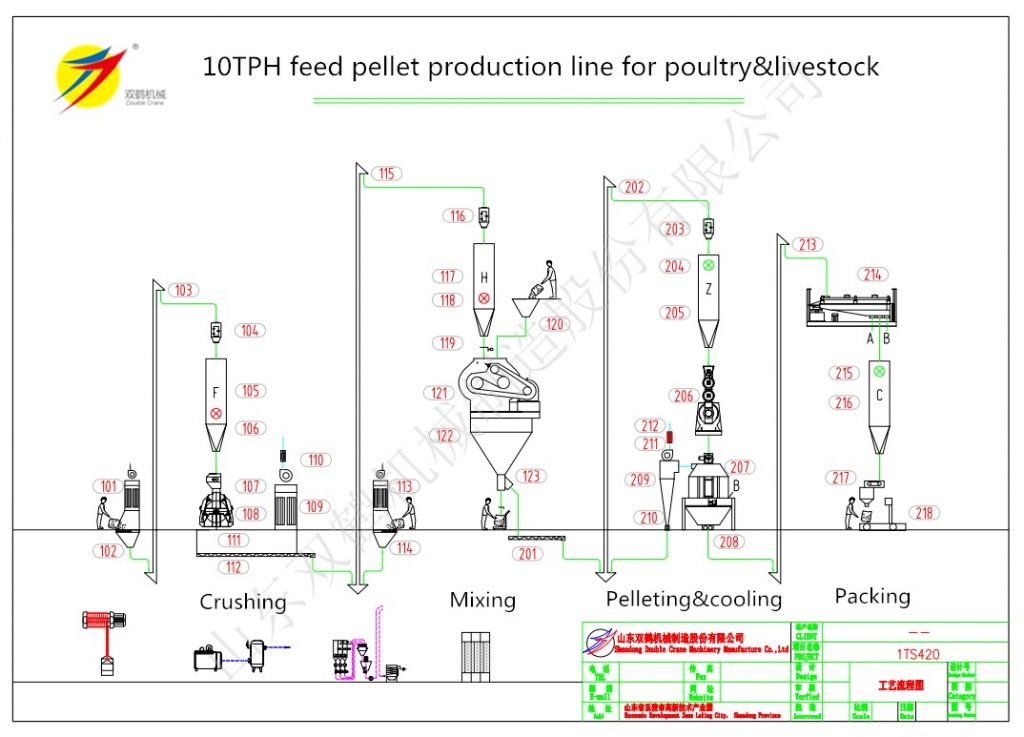

8-10T/H poultry feed plant with manual ingredients-batching has the following steps:

1.Weigh up solid raw materials such as corn and soybean,wheat and additive in proportion and percentage for crushing and mixing.

2.put a batch of solid raw material into feed hammer mill for crushing by dust removal and pre-cleaning and iron removal to avoid machines damage.

3.After crushing, a bucket elevator can transport the crushed particles by bin into feed mixer, at the same, the additive are lifted into feed mixer by bucket elevator. In the mixing section, all the particle and powder are mixed homogeneously, you also can add the liquid, oil and molasses to improve the feed taste.

4.The next step is to pelletize after mixing, but if you need some feed mash, a pneumatic Tee can shunt the feed mash into packing machine as show 207 in flow chart. Others are shunted by bin into feed pellet making machine.

For pelletizing section, it needs to add a boiler to supply the steam for conditioning to improve feed quality and feed pellet shaping and sterilize.

5.The feed pellet produced are about 60-80 degrees centigrade , the cooling machine is necessary to cool down 3-5 degrees centigrade with counterflow cooling principle to avoid feed pellet surface crack with good cooling effect.

The cooling time is controlled by double level indicators: high and low level indicator, when the feed pellet is up to high level indicator to discharge, if the feed is reach to low level indicator to stop discharging.

6.The vibrating screen are used to sieve the similar feed pellet for next packing.

7.Automatic packing scale can realize bag clipping,packing ration and bag seaming and feed pellet package conveying.